1.陶艺服饰配件的制作工艺

Craftsmanship of ceramic art accessories

制作陶艺服饰配件的工具、材料与一般制陶工具基本相同。但是由于陶艺服饰配件的尺寸应适合服饰配件的佩戴需要,一般不能太大、过重,所以除了一般的工具以外,还需要增加一些适合小件器物制作的陶艺工具。有些工具并不是专业的陶艺工具,但可根据需要作为专业工具;也可以借助一些雕塑工或雕刻工具,甚至可以自己动手制作适合使用的工具。

The tools and materials for making ceramic art accessories are basically the same as those for general ceramic tools.However,since the size of ceramic art accessories should be suitable for the wearing of clothing accessories,it is generally not too big or too heavy,so in addition to the general tools,it is necessary to add some ceramic tools suitable for small parts.Some tools are not professional ceramic tools,but can be used as professional tools as needed; you can also use some sculptors or engraving tools,or even make your own tools.

(1)主要陶艺工具及应用。

Main ceramic tools and applications.

擀泥棍:用于把泥土擀成均匀的泥片,但作陶艺服饰配件需要的尺寸相对较小,故选择小型的擀泥棍,或是借用一小段圆柱木棍擀出泥片即可。

Clay stick:used to make the soil into a uniform piece of mud,but the size required for ceramic accessories is relatively small,so a small mud stick,or a small piece of cylindrical wooden stick could be chosen and used to pull out the mud.

木拍:用于拍打泥料,混合不同的泥料。

Wood pat:used to beat mud and mix different mud.

海绵:吸水、干燥、擦拭、清理坯体。

Sponge:absorb,dry,wipe,and clean the body.

不锈钢刮片、双面刀片、美工刀片等:清理坯体

Stainless steel scraper,double-sided blade,artist blade,etc.:cleaning the blank

钢丝:切割泥土、肌理制作。

Steel wire:cutting clay and texture.

木刀:切割泥土、坯体表面处理。

Wood knife:cutting soil,body surface treatment.

砂纸:打磨坯体表面和底部。

Sandpaper:sanding the surface and bottom of the blank.

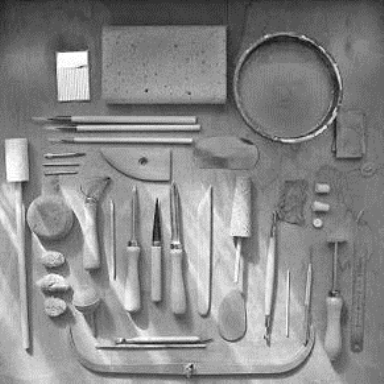

锯条:切割泥土、肌理制作(图4-66)。

Saw blade:cutting clay and texture (Figure 4-66).

(2)其他工具。

Other tools.

木制雕塑刀:可做坯体表面装饰图案的雕塑。

Wooden sculpture knife:a sculpture that can be used as a decorative pattern on the surface of a blank.

木刻刀:坯体表面装饰图案的刻画。

Woodcutting knife:the depiction of the decorative pattern of the surface of the blank.

紫砂钻孔工具:坯体湿润时给泥珠、泥片钻孔。

Purple sand drilling tool:Drill holes for mud and mud when the body is wet.

小钻头:坯体干燥时大小泥珠的钻孔。

Small drill bit:Drilling of large and small mud beads when the blank is dry.

美工刀:泥土切割。

Utility knife:dirt cutting.

尖嘴钳:金属配件的安装与调配(图4-67)。

Needle-nose pliers:installation and deployment of metal fittings (Figure 4-67).

2.成型工艺

Molding Technique

(1)泥条成型。

Mud strip molding.

以泥条为基础的成型方法,可以单独使用,也可以结合其他技法进行成型。以手工搓出的泥条与挤泥器挤出泥条来成型的陶艺服饰配件的区别是:手工搓制的泥条手工韵味十足,但是规整性较差;挤泥器制作的泥条有均匀的形态,较少变化,适合做规则的设计。泥条的大小粗细可以从几毫米到几厘米,根据需要变换即可。

图4-66 陶艺工具

Figure 4-66 Pottery tools

The mud-based molding method can be used alone or in combination with other techniques.The difference between the handcrafted mud strips and the clay pottery extruded clay strips is that the handmade mud sticks are full of charm,but the regularity is poor; the mud strips made by the muder are evenly distributed.The shape,less change,is suitable for the design of the rules.The size of the strip can vary from a few millimeters to a few centimeters,as needed.

泥条的长短随意性较强,但是考虑到干燥和烧成的收缩,应该略微放大。泥条的卷曲也要注意干湿程度,幅度较大的卷曲需要在含水量高的泥条上进行;卷曲的幅度如果较小,则相对容易,只要把握泥条不变形、不开裂就可以了。

The length of the strip is more random,but it should be slightly enlarged considering the shrinkage of drying and firing.The curling of the mud strip should also pay attention to the degree of dryness and wetness.The curl with a large amplitude needs to be carried out on the mud strip with high water content;if the curl is small,it is relatively easy,as long as the mud stick is not deformed or cracked.

图4-67 其他工具

Figure 4-67 Other tools

泥条与泥条之间的相互连接应在泥土湿润的情况下进行,这样便于各种形状、角度的选择与调配;泥条之间应用工具或是手指黏连、压紧,以防干燥和烧成过程中的开裂。干燥后的泥条连接相对比较复杂,应在两个相接的部分加水以湿润泥土,再以泥浆连接。

The interconnection between the mud strip should be carried out under the condition that the soil is wet,so that various shapes and angles can be selected and blended; tools or fingers can be adhered and pressed between the mud strips to prevent drying and burning,and cracking in the process.The connection of the dried mud strips is relatively complicated.Water should be added to the two adjacent parts to wet the soil and then connected by mud.

泥条表面基本上是没有肌理的,泥条的面积较小,肌理的制作在整个过程中不易被保留,尤其是细小的肌理比较容易在制作中被磨光和减弱。

The surface of the mud strip is basically free of texture,and the area of the mud strip is small.The production of the texture is not easy to be preserved throughout the process,especially the fine texture is easier to be polished and weakened in the production.

卷曲的泥条应在最柔软、湿润的情况下进行,卷曲过程中要保持水分,一旦失去水分,泥条就容易开裂。泥土湿润时,泥土的柔韧性很强,把泥土弯曲成任意角度都相对容易,缺点是容易变形,不易保持所需要的造型。较为干燥时弯曲泥条就要注意湿度的把握。

Curled mud strips should be curled in the softest and moist condition.Keep the moisture during the curling process.Once the moisture is lost,the strips will crack easily.When the soil is wet,the soil is very flexible,and it is relatively easy to bend the soil to any angle.The disadvantage is that it is easily deformed and it is not easy to maintain the desired shape.When drying the mud,it is necessary to pay attention to the humidity.

泥条成型配件的孔,可以在“半干”时直接穿制,或是泥条卷曲成的孔可以直接利用,不需要钻孔。

圆形泥条是最简单的泥条形态,是方形和不规整形泥条的制作基础。原则是只要搓泥条时均匀规整,尽可能避免中间存在气孔。方形泥条是在圆形泥条上用平面工具压成水平的形状,也可以使用挤泥器来制作。

The holes in the mud-formed fittings can be worn directly in the “semi-dry” or the holes in which the mud strips are crimped can be used directly without drilling.

Round mud strips are the simplest form of mud strips and are the basis for the production of square and irregular shaped mud strips.The principle is that as long as the mud is evenly regularized,it is avoided as much as possible in the middle.Square mud strips are pressed horizontally on a round mud strip with a flat tool,or they can be made using a clay mixer.

泥条卷曲可以形成变化丰富的形状,自由而多变。泥条根据需要也可以单独使用,这可以作为条形配件的坯体。泥条的制作可以是规整的,也可以是很随意的。泥条的分段切割形态最适宜环绕或黏合成为珠子,这种泥条可以是方的,也可以是圆的,甚至可以是不规则的。泥条卷曲也可以成为球状,这也为泥条成型和泥珠成型之间的变换提供了丰富的可能。

The mud strip curls can form a rich and varied shape,free and changeable.The mud strip can also be used separately as needed,which can be used as a blank for the strip fitting.The production of the mud strips can be regular or very random.The segmented cut form of the mud strip is most suitable for wrapping or bonding into beads.The strips can be square,round,or even irregular.The mud strip curl can also be spherical,which also provides a rich possibility for the transformation between the mud forming and the mud forming.

挤泥器可以制作出各种各样美丽的泥条,出泥口的形状各异,使得挤出的泥条也就有了各种的形态。根据使用的泥土的干湿程度不同,挤出的泥条也有一定的变化。

The squeezing device can produce a variety of beautiful mud strips,and the shapes of the mud outlets are different,so that the extruded mud strips have a colorful form.Depending on the degree of dryness and wetness of the soil used,the extruded mud strips also have some changes.

湿润的泥土挤出的泥条柔软平滑,较干的泥被挤出后容易有细小的开裂肌理。不同的出泥口挤出的泥条形状各异,给配饰的设计带来多种可能(图4-68)。

The mud strips extruded from the moist soil are soft and smooth,and the dry mud tends to have a fine cracking texture after being extruded.The different types of mud strips extruded from the mud outlets have different shapes,which brings many possibilities to the design of the accessories (Figure 4-68).

图4-68 泥条成型

Figure 4-68 Mud strip molding(https://www.daowen.com)

(2)泥板成型。

Molten plate forming.

在陶艺服饰配件的制作过程中,因为尺寸一般都偏小,一般称为泥片成型。它指的是根据自己的设计构思,用工具或手工把泥拍打成薄泥片,切割成一定的尺寸,一般从1~2cm,最后在泥片上进行切割与表面的肌理制作(图4-69)。

In the production process of ceramic art accessories,because the size is generally small,it is generally called mud molding.It refers to the design of the idea,using tools or hand-made mud to make a thin piece of mud,cut into a certain size,generally ranging from 1 cm to 2 cm,and finally cut and surface texture on the mud sheet (Figure 4-69).

图4-69 泥板成型

Figure 4-69 Mud Forming

(3)肌理的制作。

Fabrication of texture.

泥片表面的肌理制作要注意如果是在泥片成型后再刻画或进行浅浮雕而出现的肌理,应注意保证泥片的原始厚度和体积关系,防止雕刻过程中破坏泥片的基本形态并带来大的变形;如果是利用泥土本身的肌理,那么就要防止在切割和制作过程中手工操作时破坏泥土的自然肌理。

因为泥土柔软的特性,泥片的成型在制作过程中还可以借助一些外在的辅助材料来支撑形态的塑造,或利用工具刮泥形成自然堆积的肌理;也可以运用一些有肌理的材料,如纸、树叶、布料进行支撑和压印。虽然这些材料都属于有机物,入窑烧成后就会消失但也不可滥用,因为有些材料的拉伸性能较差,若是全部借助外部条件进行定型,泥土在干燥过程中不断收缩,而支撑材料并不能同步收缩,那么泥土就容易产生干裂(图4-70)。

The texture of the surface of the mud sheet should be noted that if the texture is formed after the mud sheet is formed or embossed,the original thickness and volume relationship of the mud sheet should be ensured to prevent the basic shape of the mud sheet from being damaged during the carving process.It brings great deformation; If it is to use the texture of the soil itself,it is necessary to prevent the natural texture of the soil from being destroyed by hand during the cutting and manufacturing process.

Due to the soft nature of the clay,the formation of the mud sheet can also be supported by some external auxiliary materials during the production process,or the tool can be used to form a naturally deposited texture; some texture materials can also be used,such as Paper,leaves,and fabric are supported and embossed.Although these materials are organic,they disappear after being fired in the kiln,but we can’t abuse them because some materials have poor tensile properties.If all are shaped by external conditions,the soil shrinks during the drying process,and since the support material can’t shrink synchronously,the soil is prone to chapped (Figure 4-70).

图4-70 白色繁星陶瓷首饰 吉姆·杰斯提斯

Figure 4-70 Ceramic Jewelry pewter starbursts by kim justice

3.辅助材料

Auxiliary materials

可借助外部辅助材料进行卷曲和支撑泥土,在泥土柔软湿润时进行弯曲和定型,以达到所需的形态。在泥土半干燥时,把辅助材料脱离原始泥坯,这样既保留了泥土肌理,又不至于破坏泥片的造型。这个过程的工艺要求是要很好地把握泥土的收缩特性,在泥土达到不黏手的时候就予以拆除,以保留需要的肌理,同时也避免了开裂的危险。

We can use external auxiliary materials to curl and support the soil,bending and shaping when the soil is soft and moist to achieve the desired shape.When the soil is semi-dry,the auxiliary material is removed from the original mud,which retains the texture of the soil without destroying the shape of the mud.The process requirement for this process is to have a good grasp of the shrinkage characteristics of the soil and to remove the soil when it is not sticky,to preserve the desired texture and to avoid the risk of cracking.

把有肌理的辅助材料,如有网格的塑料布覆盖在泥土上,把泥土连同塑料布卷曲成一样的形状,在泥片具有了可支撑的硬度时就把塑料布拆除,这样泥土上既留下了网格的细致肌理,又不会在干燥过程中出现开裂。借助其他一些本身具有肌理的材料,可以把肌理转移、应用到泥片上,这种方法直接、有效。

如制作发夹等有一定弯曲程度的泥坯时,如果是平放在桌面上,干燥和烧成后是不符合发夹的使用功能的。因此,在制作时就应该把泥坯做成弯曲的形态,并放置在弯曲的支撑泥块上,缓慢地干燥,并将二者同入窑烧制,烧成后才能够最大限度地符合发夹的弯曲弧度。制作过程中还必须考虑收缩的比例,适当地放大制作的尺寸,在烧制后能够足以覆盖钢夹。

Cover the soil with a protective auxiliary material,such as a meshed plastic sheet,and curl the soil into a shape with a plastic sheet.When the sheet has a supportable hardness,remove the plastic sheet,so that the soil remains.The fine texture of the mesh is printed on the soil without cracking it during the drying process.With the help of other materials with their own texture,the texture can be transferred to the mud,directly and effectively.

If the mud mold requires a certain degree of bending,such as a hair clip,it will not conform to the function of the hairpin after drying and burning if it is placed flat on the table.Therefore,the mud should be made into a curved shape during the production,and placed on the curved supporting mud,slowly dried,and the two are fired in the kiln,and the maximum curved curvature can be matched with the clamp after firing.The proportion of shrinkage must also be taken into account during the production process,and the dimensions produced are appropriately enlarged to cover the steel clip after burning.

4.组合构成

Combination composition

在泥片和泥片之间的组合并列构成图案化的设计,可以把泥片切割成为需要的形态,进行叠加或组合。

如发夹的泥坯就是以泥片为基本成型元素,把泥片切割、挤压并进行组合构成。把泥片切割成为相同相似的形态进行叠加、组合时要注意泥片单元之间的黏合,要在泥片湿润时结合紧密,或是在半干燥时用泥浆进行连接,并保证两个相接部位之间干湿程度的一致(图4-71)。

The combination of the mud pieces is juxtaposed to form a patterned design,and the piece can be cut into a desired form,superimposed or combined.

For example,the mud of the hairpin is made up of mud sheets as the basic forming elements,and the pieces are cut,extruded and combined.Cut the mud pieces into the same similar form for superposition and combination.Pay attention to the adhesion between the mud pieces.It should be tightly combined when the mud pieces are wet,or connected with mud when semi-drying,and ensure two phases.The degree of dryness and wetness between the joints is the same(Figure 4-71).

图4-71 泥片成型的陶瓷首饰 卢卡·特帕尔蒂

Figure 4-71 Ceramic jewelry with clay slices luca tripaldi

(1)加法和减法。

Addition and subtraction.

泥片成型的外形,可以顺应泥片的自然边缘与外形,也可以根据需要进行相接、分割等设计,在泥片上做合适的加法和减法。

The shape of the mud piece can conform to the natural edge and shape of the mud,and can also be connected and divided according to the needs,and appropriate addition and subtraction can be done on the mud piece.

加法(主要指泥之间的黏连与结合),适合在泥土湿润的时候进行,可在泥片上增加泥团、泥片、泥条等。如果在干燥时做加法,就要注意两部分的干湿程度,如果干湿一致,那么调同种泥土的泥浆,把两个相接的位置打湿,用泥浆连接就行;如果两部分的干湿度不均匀,不能相接,务必等到两部分的干燥程度完全一致时再连接,因为两部分干湿不均容易引起干燥过程中的开裂,烧成时可能脱落和开裂。

Addition (mainly refers to the adhesion and bonding between the mud),is suitable for the soil when the soil is wet.We can add mud,mud,mud and so on on the mud.If adding during drying,pay attention to the degree of dryness and wetness of the two parts.If the dryness and wetness are the same,adjust the mud of the same kind of soil,wet the two connected positions,and connect with the mud; if the two parts are dry,the humidity is not uniform and cannot be connected.It is necessary to wait until the dryness of the two parts is completely the same,because the two parts may fall off and crack when burned if they are unevenly wet and dry,causing cracking during the drying process.

减法(主要指泥板的刻画等装饰),一般适合在泥土干燥的时候进行,因为在泥片湿的时候刻画或做装饰,都很容易把泥土连带起来,黏连在刀上,增加工作的难度。而在干燥或半干时雕刻或塑造,那就相对容易得多,可以比较容易地刻画出所需要的线条和形态。干燥时雕刻、塑造要求非常准确,如果刻画错误,那就不易补救,因为泥土干后再相接不容易。

Subtraction (mainly refers to the decoration of the mud board,etc.),is generally suitable for the drying of the soil.When the mud is wet,it is quite likely to connect the soil,and stick it to the knife,increasing the difficulty.It is relatively easy to sculpt or shape when dry or semi-dry,and it is easier to describe the lines and shapes needed.The requirements for engraving and shaping during drying are very accurate.If the sculpting is wrong,it is not easy to remedy,for it is not easy to connect after the soil is dry.

(2)泥片的穿孔。

Perforation of the mud piece.

泥片的穿孔要选择合适的时机,一般来说是在干燥初期,泥土略微失去水分,不粘连工具且具有了一定硬度的时候,用尖刀或钻孔的工具在需要穿孔的地方进行。一般不主张在干燥后期穿孔,因为那样很容易使制作完的泥片发生破裂。

The perforation of the mud piece should be selected at the right time.Generally speaking,in the initial stage of drying,when the soil loses moisture slightly,when the tool is not stuck and has a certain hardness,it is carried out in a place where it is needed with a sharp knife or a drilling tool.Perforation in the late drying stage is generally not recommended because it is easy to break the finished mud sheet.

(3)卷曲。

Curling.

泥片的卷曲特别需要注意泥土的干湿,因为一般的瓷泥可塑性较差,卷曲时容易开裂。泥片较薄,容易卷曲成型,造型较为准确,缺点是泥片太脆弱,易碎,在烧制之前不易保存。若泥片较厚,则相对安全得多,不易破损;但是还要注意泥片的重量,太厚就显得笨重,不符合服饰配件的装饰功能。泥片的开裂在干燥的初期如果得到控制就不易扩大。泥土表面的浅层裂纹是可以接受的,如果全部裂透了整个泥片就可能在烧成过程中断裂(图4-72)。

The curling of the mud sheet requires special attention to the wetness and dryness of the soil,because the general porcelain clay is poor in plasticity and is easily cracked when curled.The mud sheet is thin,easy to curl and form,and the shape is more accurate.The disadvantage is that the mud sheet is too fragile and brittle,and is difficult to store before burning.If the mud is thicker,it is relatively safer and less prone to breakage; but it should also pay attention to the weight of the mud piece.If it is too thick,it will be bulky and not suitable for the decorative function of the clothing accessories.Cracking of the mud sheet is not easily expanded if it is controlled at the beginning of drying.Shallow cracks on the surface of the soil are acceptable.If all of the mud is cracked,it may break during the firing process (Figure 4-72).

图4-72 泥片卷曲成型的陶瓷首饰

Figure 4-72 Clay-formed ceramic jewelry

(4)泥珠成型。

Mud beads molding.

泥珠成型是各成型方法中最为自由而富有表现力的一种。取一小团泥在手心里搓制,就成为一个规则或不规则的泥球,可以保持圆形,也可以压扁成为扁形珠,更可以在泥珠的表面做各种装饰,刻、画、印、雕等均可。甚至是简单地随手搓出的泥团,都可能成为泥珠造型的原坯(图4-73)。

Mud beads molding is the most free and expressive of all molding methods.Take a small handful mud in the palm and rub,it becomes a regular or irregular mud ball,you can keep it round,you can also flatten it into a flat bead,you can make various decorations on the surface of the clay,engraved,Painting,printing,carving,etc.Even the mud that is simply pulled out by hand can become a mold of mud bead shape (Figure 4-73).

图4-73 泥珠成型

Figure 4-73 Mud beads molding

泥珠的形态,可以手工搓出,也可以由泥条分段切割、揉扭,或是由泥片切割、卷曲变形来制成。因此,泥珠的形状不局限于圆形、方形、椭圆形、三角形、锥形、不规则形等,自由而富有变化。当然有时泥珠的范围更宽泛,只要是视觉上可以成为一个团形的,都可以称为泥珠,尺寸基本不受限制。

The shape of the mud can be cut out by hand,or it can be cut or twisted by the strips,or cut and curled by the mud.Therefore,the shape of the mud beads is not limited to a circular shape,and a square shape,an elliptical shape,a triangular shape,a tapered shape,an irregular shape,and the like can be freely and varied.Of course,sometimes the range of mud beads is wider,as long as it can be visually a cluster.It can be called mud beads,and the size is basically unlimited.

手工制作的泥珠一般来说都是实心的,泥珠较小的尺寸决定了制作空心泥珠是比较困难的。泥珠的制作过程相对是简单和迅速的,因此在手工制作的过程中也不需要过多地考虑形态的一致,手工制作即可;但是在产业化的过程中,就必须使用模具成型以保证形态的规整一致。

Handmade clay beads are generally solid,and the small size of the clay beads makes it difficult to make hollow clay beads.The process of making clay beads is relatively simple and rapid.Therefore,it is not necessary to consider the uniformity of the shape in the process of hand-made,and it can be handmade.However,in the process of industrialization,mold molding must be used to ensure The shape is consistent.

把已干燥的泥珠坯体进行表面的小块切割,给小小的泥珠以空间的变化,在泥珠表面形成形状各异、大小不等的平面,产生微妙的体积感。或者可以在泥珠的表面作出或深或浅的各种肌理,都是改变泥珠表面形态的有效方式。

The dried clay bead body is cut into small pieces on the surface to change the space of the small mud beads,and planes of different shapes and sizes are formed on the surface of the mud beads,resulting in a subtle volume feeling.Or it can be made on the surface of the mud or deep or shallow texture,which is an effective way to change the surface morphology of the mud.

(5)模具成型。

Mold forming.

模具成型是借助石膏或其他材质的模具,进行注浆或印坯的成型方法。模具的使用在陶艺服饰配件的工业化生产中,对量化制作程度有着直接的影响,适应制作的是规整、统一的造型和数量上的快速积累。在进行小批量制作时,也可以根据需要使用模具成型的工艺。

用模具制作陶瓷服饰配件与陶瓷生产的一般工艺一样,首先要用泥土或石膏做出模种,然后翻石膏模。待模具干燥后,采用注或印坯的方法来制作坯体。印坯出来的坯配件可以单独使用,还可以把压印出来泥坯重新排列和组合,形成新的造型。

Molding is a method of grouting or printing by means of plaster or other material.The use of molds has a direct impact on the degree of quantitative production in the industrial production of ceramics accessories.The production is a regular,unified shape and rapid accumulation of quantity.In the case of small batch production,the mold forming process can also be used as needed.

The use of molds to make ceramic clothing accessories is the same as the ceramic production process.First,the mold is made of clay or plaster,and then the plaster mold is turned.After the mold is dried,the blank is formed by a method of injecting or printing.The blank parts from the blank can be used separately,and the embossed mud can be rearranged and combined to form a new shape.

免责声明:以上内容源自网络,版权归原作者所有,如有侵犯您的原创版权请告知,我们将尽快删除相关内容。